Most digital machining is based on a subtractive process where a block of material is machined down using milling techniques to achieve a desired surface. The difference in what we are doing is using the robot to apply an addative process where we have settled on a 2 part foam to be applied in layers then selectivley machined away.

With a limited amount of time to get this rolling we had to make a decision fairly quick regarding the material, research pushed toward a soy based foam that was more eco-friendly but in respect of time and the ability to actually talk to people willing to work with us we fell short and ended up going with what we could get quickly and fairly local.

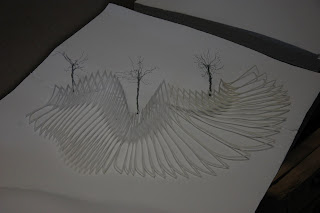

Following are posts of some of our tests.

video of initial foam test http://www.youtube.com/watch?v=aBof2ufOFrA

Initial test using Froth-Pak foam, this kit was available from the hardware store for around $40 and available in bulk sizes by freight. So along with the Great Stuff it was a good place to start

Testing the Great Stuff (canned foam)

Testing the Froth Pak

We found this stuff to work rather well, skinned over within 20 seconds or so, and by the time I made one round (roughly a 30" diamater circle) it was solid enough to support itself

Although we did find that as the material ran out of the small cans the pressure started to decrease and the mixture became speratic and inconsistent with the initial layout.

Although we did find that as the material ran out of the small cans the pressure started to decrease and the mixture became speratic and inconsistent with the initial layout.